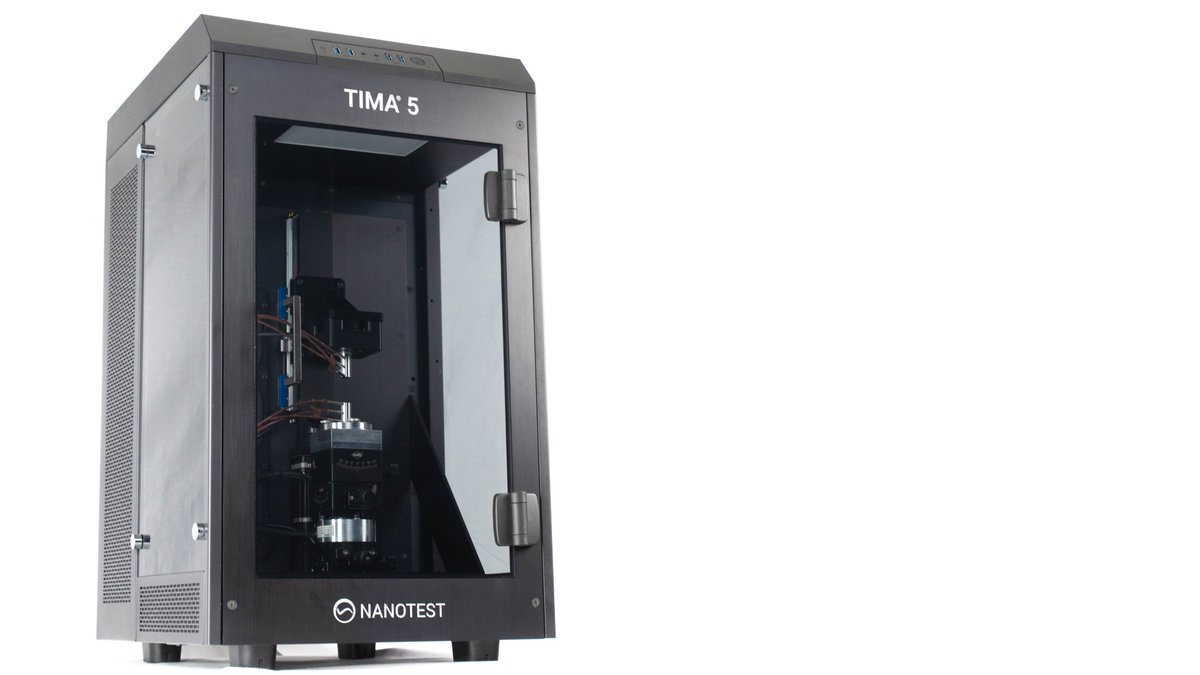

TIMA 5

Thermal Interface Material Analyzer

- Category: Thermal material characterization

- Standards: ASTM D5470

- Targets: Thermal interface material

- Limit: 1 mm²K/W

TIMA 5

Thermal Interface Material Analyzer

The analysis of thermal interface materials has never been so simple and comprehensive at the same time. The TIMA provides a bridge between science and industry through a high degree of functionality and unsurpassed ease of use.

The Thermal Interface Material Analyzer - TIMA 5 - is a universal system for thermal and thermo-mechanical characterization of thermal interface materials as well as other material classes with low to medium thermal conductivities. It fully complies with ASTM D5470, an industry-wide respected and commonly used standard for TIM characterization, that comes with necessary variability to adapt to most application scenarios.

The system is highly compact and fits into any laboratory, cold water supply provided. A one-day training is enough to fully understand the device and be able to perform all types of characterizations and material studies. This is our promise.

TIMA Product Video

This 3-minute video is a brief summary of TIMA's vast pool of features and strengths.

Watch on YouTubeASTM D5470

Superior TIM characterization

The ASTM standard D5470 describes the procedure to characterize thermal materials and to obtain the bulk thermal conductivity and theinterface resistance. While the first value is material-specific, the second is most context-sensitive and of increasing importance for modern applications. Especially for TIM characterization, ASTM D5470 is superior to any other existing method.

In general, the interface resistance is dependent on the following paramters, all of which are configurable options in TIMA:

- The TIM and its composition (matrix, particles etc.)

- Surface material, quality and roughness

- Contacting force and adhesion

- Surface temperatures

The driving force

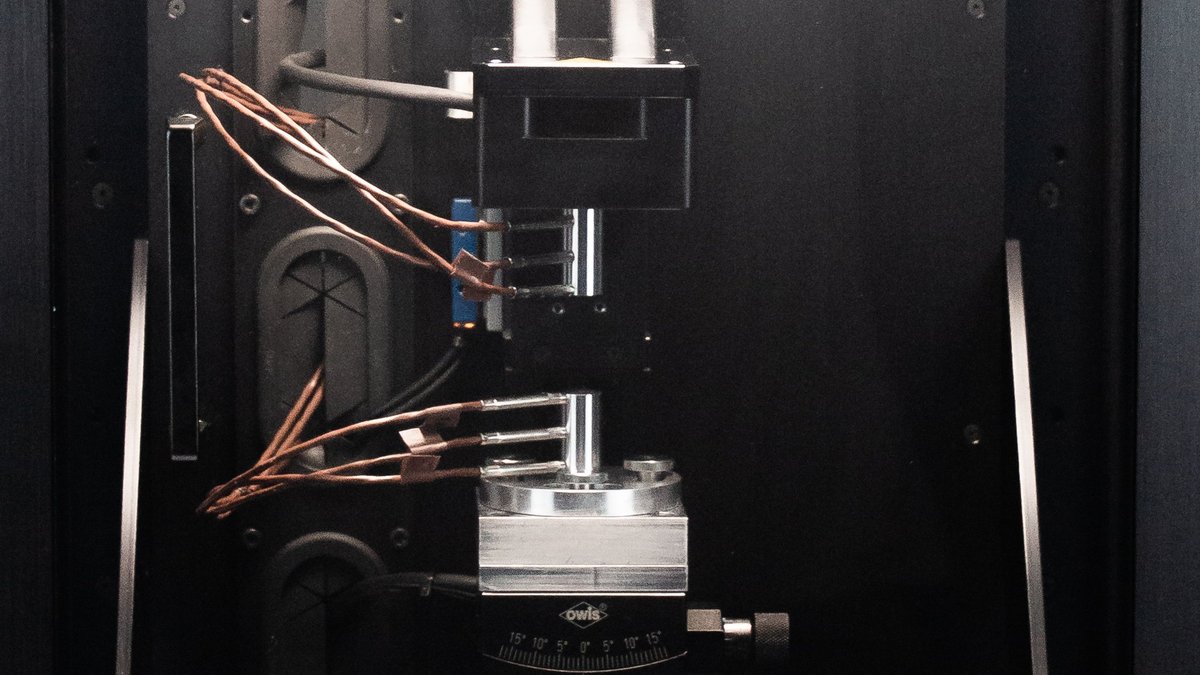

A powerful motor allows compression and tension of sample material with up to 300 N of normal force. This translates - depending on the sample cross-section - into up to 3 MPa / 430 PSI. This covers any considerable strain in TIM applications and allows to obtain comprehensive data for material development and to provide in your datasheets.

While controlling the force applied to your sample, TIMA precisely monitores the sample thickness with few microns resolution to give exact information of material compression and to monitor the effective thermal conductivity of the sample.

Boost your pace

Automated and standardized measurements

Measurements in TIMA can be carried out fully automatically. Insert material, start measurement and become productive on another front. This involves standardized ASTM D 5470 measurements at varying thicknesses or cyclic tests on pastes or gap fillers to evaluate their durability. All relevant variables are monitored in-situ, recorded into files and can be viewed quickly with the associated software. You can at any time understand how far your measurement or the sample's aging process has progressed and decide to intervene at the right moment to start the next measurement. You will lose less time and boost your development pace.

Additionally, the TIMA software supports definition of measurement procedures that can be used to establish standard procedures in your company and enhance repeatibility and comparability.

TIMA at DuPont SVTC

The DuPont Silicon Valley Technology Center is a facility for innovation, located at the very cradle of technology in Silicon Valley, USA. Its focus and main purpose is for engineers and scientists to meet and to pursue novel ideas, being provided with modern, cutting-edge technology and equipment to be without boundaries and shortest times from idea to realization.

The shared video shows TIMA as one centerpiece of their materials research and innovation lab, presented by Dr. Claire Wemp, a thermal applications engineer of DuPont who has been active in thermal interface material development for several years. Equipped with TIMA, she is able to quickly assess the quality and thermal performance of TIMs and other materials quickly and with high resolution.